Good insulation doesn’t just add layers around heat sources. It must closely fit the dimensions of the components to minimize heat loss and increase ease of use.

But when it comes time to decide the makeup of your insulation blanket, do you know anything about the materials that go inside?

The team at Firwin Corporation has extensive knowledge about insulation materials and is able to carefully match your equipment with custom insulation covers and liners, made of materials best suited for your unique application. We provide a wide selection of insulation materials to customers, ensuring that you obtain an insulation solution that fits your equipment and your facility’s needs.

Factors to Consider

Choosing the right material for your insulation covers is essential—and not every material is suited for every application. Here are five different factors that would affect material selection:

1. Maximum Temperature Range

Perhaps one of the most important considerations in insulation materials is the temperature range. Insulation materials should meet or exceed the high end of your standard operating temperatures and should account for potential high-temperature extremes. Insufficient insulation can be costly and dangerous.

2. Protection from the Elements

Gauge your equipment’s exposure to elements such as water, debris, chemicals, and UV radiation. You need to choose materials for your insulation covers which can withstand these environmental factors without degrading. While some protective elements may be added to insulation materials, others may cause stiffness or impact ease of use. All our materials have their own set of properties, but some are better at handling extreme environments than others. Depending on your equipment’s exposure, one kind of material may be better suited as insulation than others.

3. Safety and Regulatory Requirements

It’s important to always check the manufacturer’s certifications for facility equipment, especially where related to safety. Some industries also have more exhaustive UL and safety standard requirements than others. Firwin guarantees that our insulation covers are made with high-quality materials and our company is ISO 9001-certified. Our team of engineers and technicians work hard to meet or exceed all safety and regulatory requirements. Some safety requirements like fire retardancy will impact which materials we choose for your insulation based on the material properties.

4. Space

Space can quickly limit the type and amount of insulation you can add to a given system. You’ll want to look for thinner, flexible materials for use near tight system configurations and controls, but will have less restrictions on material type in more spacious areas.

5. Touch Temperature

While the maximum temperature factor details how much heat your insulation covers can safely handle, the “touch” temperature factor details the handling temperature on the outside of the cover. Some insulation materials will only reduce ambient heat in environments that just need lower—but not safe to touch—temperatures. Other insulation materials can thoroughly dampen heat in applications where the covers must be touched throughout the day.

While small or constrained environments may demand thinner material and/or slightly higher temperatures, a safe contact rating is still a priority for our manufacturing team. When you’re considering an adequate exterior temperature for your insulation material, it’s important to remember that fabric is safer at high temperatures than metal. Fabric doesn’t conduct heat as well as metal, so it must exceed 203° F (95°C) before becoming unsafe to touch (UL 2200).

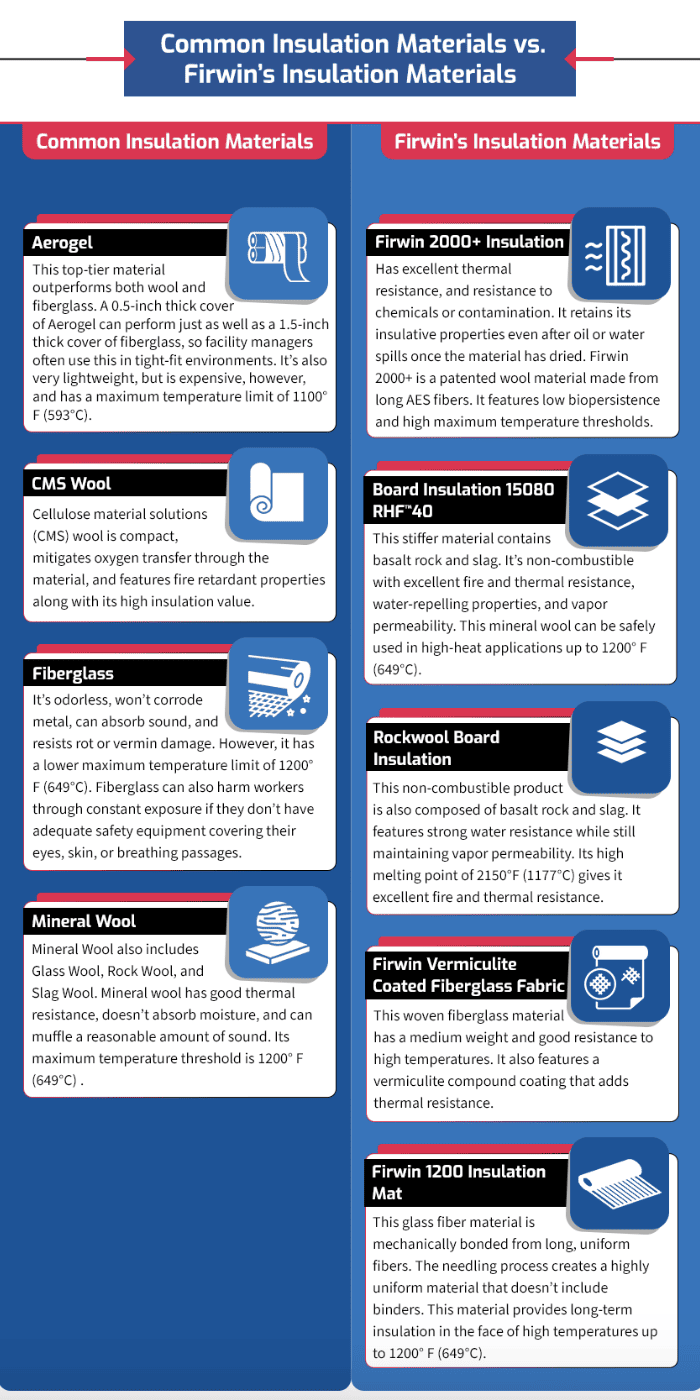

Common Insulation Materials

So what insulation materials are available when designing an insulation? Some common materials/fabrics for commercial and industrial insulation covers include:

Aerogel

This top-tier material outperforms both wool and fiberglass. A 0.5-inch thick cover of Aerogel can perform just as well as a 1.5-inch thick cover of fiberglass, so facility managers often use this material in tight-fit environments. Aerogel is also very lightweight, which makes it ideal for use near fragile or light components. The material is expensive, however, and has a maximum temperature limit of 1100° F (593°C) .

CMS Wool

Cellulose material solutions (CMS) wool is compact, mitigates oxygen transfer through the material, and features fire retardant properties along with its high insulation value. Other properties include:

- A maximum temperature limit of 2192° F (1200° C)

- Odorless

- Won’t contribute to corrosion

- Sound absorbent

- Resistance to decay, vermin, and mold

Fiberglass

Fiberglass is one of the most common insulative materials used in the fabrication of insulation blankets. Just like CMS wool, it’s odorless, won’t corrode metal, can absorb sound, and resists rot or vermin damage. However, it has a lower maximum temperature limit of 1200° F (649°C). Fiberglass can also harm workers through constant exposure if they don’t have adequate safety equipment covering their eyes, skin, or breathing passages.

Mineral Wool

The broad category of mineral wool materials includes:

- Glass wool (made from recycled glass)

- Rock wool (made from basalt)

- Slag wool (most common mineral wool, made from steel mill slag)

Mineral wool has good thermal resistance, doesn’t absorb moisture, and can muffle a reasonable amount of sound. Its maximum temperature threshold is 1200° F (649°C) .

Firwin’s Insulation Materials

Firwin Corporation uses specialty materials to keep your facility’s equipment well insulated and safe for workers. Our high-performance materials include:

Firwin 2000+ Insulation

This material has excellent thermal resistance, as well as resistance to chemicals or contamination. It retains its insulative properties even after oil or water spills once the material has dried. Firwin 2000+ is a patented wool material made from long AES fibers. It features low biopersistence and high maximum temperature thresholds.

This material has excellent thermal resistance, as well as resistance to chemicals or contamination. It retains its insulative properties even after oil or water spills once the material has dried. Firwin 2000+ is a patented wool material made from long AES fibers. It features low biopersistence and high maximum temperature thresholds.

Properties

- Rated Temperature 2192ºF (1200ºC)

- Absorbs sound

- Easy to install

- Excellent thermal stability and insulation

- High strength levels and good tear resistance

- Low heat storage

- Low irritant levels and increased softness

- Low thermal conductivity

- Minimal outgassing due to cleaning and organic matter removal during production

- Solubility in body fluids

Applications

This material is commonly used for the following applications:

- Acoustical service

- Annealing furnace linings

- Cryogenic insulation

- Expansion joint packing

- Fire protection

- Furnace kiln reformer and boiler lining

- Furnace door lining and seals

- Furnace repair

- Investment casting mold wrap

- Laboratory ovens

- Removable insulation blankets

- Stress-relieving blankets

Board Insulation 15080 RHF™40

This stiffer material contains basalt rock and slag. It’s a non-combustible material with excellent fire and thermal resistance, water-repelling properties, and vapor permeability. It has a melting point of 2150° F (1177°C) . This mineral wool can be safely used in high-heat applications up to 1200° F (649°C).

Properties

- Fabrication and lamination options available

- Chemically inert and non-corrosive

- Non-combustible

- Lightweight

- Made from natural and recycled materials; free from CFC and HCFC

- Low moisture absorption

Applications

Facility managers can use Board Insulation 15080 RHF™40 for multiple applications. Our team can manufacture the material to match different specifications without any loss in fire, thermal, and water resistance. One of the most common applications is pipe and tank wrapping thanks to the materials moisture resistance and insulating properties.

Rockwool Board Insulation 8LB

This non-combustible product is also composed of basalt rock and slag. It features strong water resistance while still maintaining vapor permeability. Its high melting point of 2150°F (1177°C) gives it excellent fire and thermal resistance.

Properties

- Easy to install and use

- Fabrication and lamination options available

- Chemically inert and non-corrosive

- Non-combustible

- Lightweight

- Made from natural and recycled materials; free from CFC and HCFC

- Low moisture absorption

Applications

This material resists physical damage and compression from impacts. It’s also a useful insulation solution for applications that require excellent thermal, fire, and moisture damage resistance.

Firwin Vermiculite Coated Fiberglass Fabric

This woven fiberglass material has a medium weight and good resistance to high temperatures. It also features a vermiculite compound coating that adds thermal resistance.

Properties

- Can withstand continuous heat during long-term applications

- May be subject to some physical degradation after extended exposure to high heat

- Has a continuous temperature threshold of 1200° F (649°C) and an intermittent threshold of 1500° F (816°C)

Applications

- Flame and high-heat barriers

- A replacement for silica or ceramic fabrics

Firwin 1200 Insulation Mat

This glass fiber material is mechanically bonded from long, uniform fibers. The needling process creates a highly uniform material that doesn’t include binders. This material provides long-term insulation in the face of high temperatures up to 1200° F (649°C).

This glass fiber material is mechanically bonded from long, uniform fibers. The needling process creates a highly uniform material that doesn’t include binders. This material provides long-term insulation in the face of high temperatures up to 1200° F (649°C).

Properties

- Easy to install due to drapability and flexibility

- Does not contribute to metal corrosion, decay, or mold

- Resistant to vermin-related damage

- Muffles sound and vibration

- Odorless

Download Firwin’s Insulation Materials Guide

Get More Insulation Material Information from Firwin

Firwin Corporation specializes in high-quality, customizable insulation covers and other insulation solutions. We create covers for a wide variety of industries and applications, including general industrial applications, diesel and gas engines, and exhaust systems.

Download our eBook, “Removable Insulation Blanket Materials — A Guide from A to Z,” for more information on selecting the best insulation blankets and materials for your facility.