At Firwin, we offer dynamic prototyping solutions to meet your unique insulation requirements. We combine years of design and engineering expertise with the latest technology to deliver cost-effective, reliable insulation products every time.

Ensure Proper Insulation Fit With Firwin’s Prototyping Capabilities

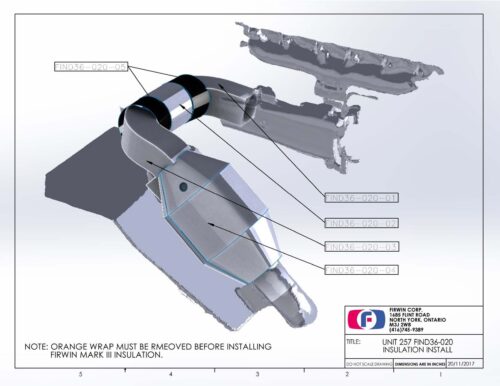

Our advanced prototyping capabilities allow us to test out designs before investing time and money in larger production runs. We work with you from design to production, making any necessary corrections and then re-testing to ensure an exact fit.

Prototyping components helps to ensure a proper blanket fit and prevent performance issues in the final product, including the following:

- Heat escaping from the equipment

- Increased energy consumption

- Potential damage to products, equipment, and personnel

Learn more about our vast prototyping capabilities below, so you can start setting the groundwork for your project with Firwin.

Prototyping From Existing Parts & Drawings

Parts 3D Printed by Firwin

Reverse Engineering

Our team can also reverse-engineer an insulation blanket from an actual blanket currently in use at your facility. We will analyze the existing product to determine its material makeup and confirm the necessary project specifications for your application. Our engineering team will thoroughly assess the blanket and its functionality, making suggestions for material and design improvements when possible.

Client Success Stories

Explore the advantages of professional prototyping for insulation blankets to achieve the right fit and construction.

Insulation Applications

Quality insulation designs can drastically reduce hazards and improve system performance in a wide range of applications. Some of the most common uses for our insulation blankets include:

Ready to Discuss Your Insulation Project? Contact Our Specialists Today

Ready to Discuss Your Insulation Project? Contact Our Specialists Today

If you need protective insulation blankets for your equipment, take advantage of our advanced prototyping process to achieve the best final product.

Firwin specializes in creating custom insulation products for OEMs, industrial clients, diesel and gas engines, and more. Since 1982, we have provided design and development solutions, insulation blanket manufacturing, and excellent customer support. We work closely with customers throughout the production process to make sure you get exactly what you need.

Reach out to Firwin to learn more about our processes and to start your next project or request a quote for pricing details.