Among the fastening systems we offer for our removable insulation blankets is Velcro. An excellent and easy to use fastener, Velcro is often used in applications which require a simple and quick fastening method. Velcro fastening does, however, come with some limitations, which users need to be aware of in order for it to function as intended.

Among the fastening systems we offer for our removable insulation blankets is Velcro. An excellent and easy to use fastener, Velcro is often used in applications which require a simple and quick fastening method. Velcro fastening does, however, come with some limitations, which users need to be aware of in order for it to function as intended.

Background – How It Works

Velcro is actually the trade name for what is generically known as ‘Hook and Loop’ fastening. The hook‐and‐loop fastener was conceived in 1941 by Swiss engineer George de Mestral who lived in Commugny, Switzerland. The idea came to him one day after returning from a hunting trip with his dog in the Alps. He took a close look at the burrs (seeds) of burdock that kept sticking to his clothes and his dog’s fur. He examined them under a microscope, and noted their hundreds of “hooks” that caught on anything with a loop, such as clothing, animal fur, or hair. He saw the possibility of binding two materials reversibly in a simple fashion if he could figure out how to duplicate the hooks and loops. It took de Mestral around 10 years to perfect the process, and Velcro was born.

Velcro Fastening on Removable Insulation Blankets

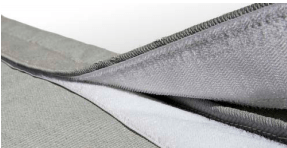

Velcro fastening systems are supplied on rolls of paired woven tapes. The materials used in making these woven tapes are typically one or more of nylon, polyester, and Nomex (a flame‐resistant meta‐aramid material developed in the early 1960s by DuPont). Each paired tape has a loop tape, with loops made from the same fiber as the woven tape, and a hook tape. The hook tape, regardless of what material the woven tape is made from, typically has nylon or polyester hooks. For example, when ordering a Nomex Velcro, even though the base tape and loops are made with Nomex, the hooks will still be made with Nylon or Polyester.

Velcro can either be used as the prime fastening system where the Velcro keeps the blanket closed, or it can be used as a secondary or complementary fastener, as in the case of ‘D rings’, where the ‘D rings’ fasten the blanket and the Velcro is only used to secure the ‘D ring’ strap in place.

Why Velcro Fastening Sometime Becomes Ineffective

Velcro tapes are temperature rated when ‘closed’ (i.e. when hook and loop are fastened). In fact clothing manufacturers always require the Velcro tape to be closed before ironing/pressing garments ‐ and which is why you should also fasten any Velcro garments before putting them in the washer / dryer! So a Nomex base Velcro with nylon or polyester hooks will have a slightly higher temperature rating (350°F / 177°C) than a polyester‐based Velcro (280°F / 138°C), as the Nomex provides some additional heat protection for the nylon / Straps with Velcro &”D” Ring Fastening System polyester hooks when the tape is in the closed state. For temperatures beyond 350°F / 177°C, stainless steel hooks are available. Depending on the base tape used, stainless steel hooked Velcro tape can be used in applications as high as 450°F / 232°C for Nomex‐based tape, to as high as 800° F / 426° C for Velcro tapes constructed completely from 300 series stainless steel. The higher one goes on the temperature scale, the more expensive the Velcro tape becomes, especially the stainless steel versions. Because of this price premium, Velcro fastening is most commonly found on removable insulation blankets used in temperature ranges which can support nylon or polyester hooks.

As mentioned, both Nylon and Polyester have a temperature tolerance up to 280°F / 138°C , beyond which they tend to break down or melt if brought into contact with a heated surface. In practice, manufacturers like to err on the side of caution, and typically call for a temperature limit of 200°F / 93°C. This means that as long as the outside temperature of the insulation blanket (the ‘cold face’) is below this temperature limit, Nylon and Polyester Velcro should function properly. For example, for a pipe of 3” or 4” diameter, with a room temperature ambient, a typical 1” thick insulation blanket would allow for an internal temperature of up to 800° F / 426° C before the outside face temperature went beyond 200°F / 93°C.

The ‘weak point’ on a Velcro fastener is typically the hooks since they are so fine. Once the hooks are damaged from contact with high temperatures the fastening tape becomes ineffective. This is the most common reason for breakdown of Velcro tapes. Even the accidental brushing of the hook tape against a hot surface is sufficient to damage the hooks. Another common cause of Velcro tape breakdown is when the loops and hooks get clogged up with dust of grime.

Are Velcro Fastened Removable Insulation Blankets Right For You?

As mentioned above, the main benefit of Velcro fastening is the ease in which an insulation blanket can be installed and removed. However, there are situations where Velcro may not be the recommended fastening method. “For low temperature applications, Velcro can be an excellent fastening method”, notes Brett Herman, Firwin’s Vice President of Sales and Customer Service. “This is especially true if the customer requires a fastening method that is easy to install and / or remove.”

As mentioned above, the main benefit of Velcro fastening is the ease in which an insulation blanket can be installed and removed. However, there are situations where Velcro may not be the recommended fastening method. “For low temperature applications, Velcro can be an excellent fastening method”, notes Brett Herman, Firwin’s Vice President of Sales and Customer Service. “This is especially true if the customer requires a fastening method that is easy to install and / or remove.”

“However, there are some drawbacks that customers need to be aware of. Firstly, most Velcro come with polyester or nylon hooks, and if these are exposed to heat approaching 280°F, the hooks can become damaged and the Velcro fastener will no longer be effective. While stainless steel Velcro hooks are an option, they are quite expensive, and even they are limited to 800° F / 426° C – so if the application is very high temperature, these hooks also pose the risk of getting damaged through accidental contact.”

“Secondly, when compared to the ‘standard method’ of fastening blankets via stainless steel lacing wire and rivets, Velcro has an added cost component, mainly from the increased labor needed to produce a Velcro blanket. So for customers looking for a ‘lowest cost’ solution, and for whom ease of installation and removal is not so crucial, an alternative fastening method would be better suited”, added Brett.

“Secondly, when compared to the ‘standard method’ of fastening blankets via stainless steel lacing wire and rivets, Velcro has an added cost component, mainly from the increased labor needed to produce a Velcro blanket. So for customers looking for a ‘lowest cost’ solution, and for whom ease of installation and removal is not so crucial, an alternative fastening method would be better suited”, added Brett.

Proper Care of Velcro Fastened Removable Insulation Blankets

The recommended use of Velcro when used on insulation blankets, for hot Removable Insulation Blanket with lacing wire & rivet fastening Other blanket fastening methods: Snaps, Straps, Springs equipment and heater bands, is to install and remove blankets when the machine or surface is cold.

Firwin blankets are designed to ensure that Velcro fastenings with nylon / polyester hooks are mounted on the cold side of the blanket insulated from the hot surface by a suitable insulation layer. To be safe, we like to add a buffer to the temperature limit, and call for a temperature below 200⁰F [93 ⁰C] to make sure that the hooks will not be damaged. Care should be taken at all times not to allow the hook side of the blanket to brush up against such a hot surface.

As well, blankets should not be kept in grimy areas, or any place where dirt or molten plastics can get into the Velcro.

Other Articles: Insulation Blankets Taking Charge ∙ Covers for Industrial Valves

Comments are closed